News

- Industry news

Industry news

Plastic science knowledge - precision injection mold

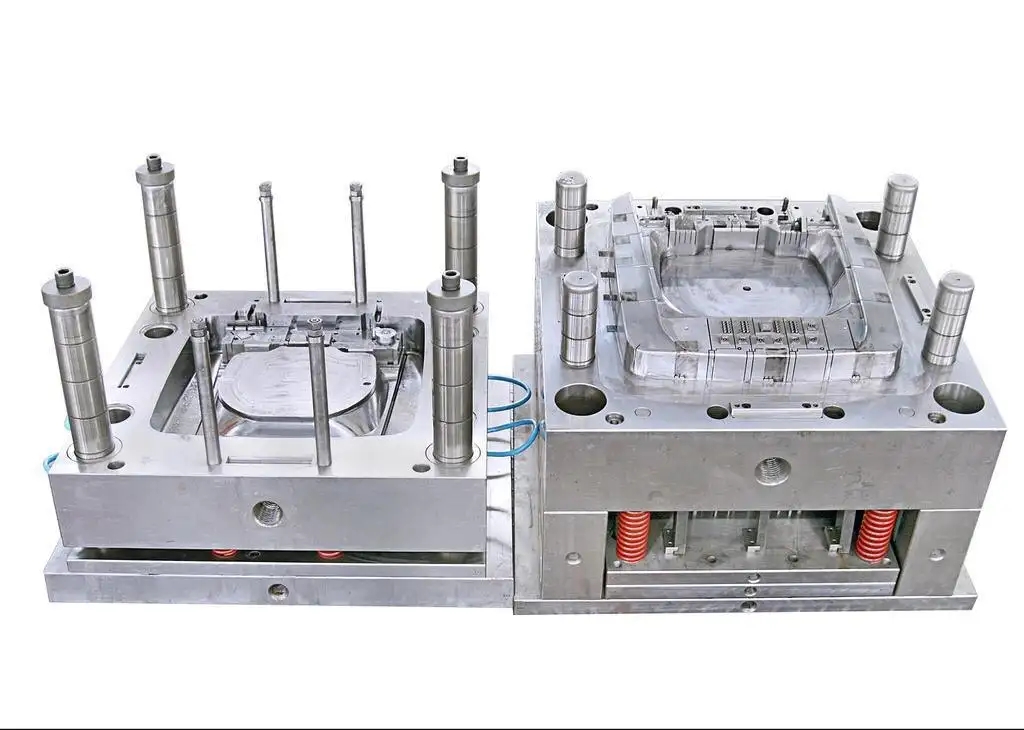

What is precision injection mold?

Precision injection mold refers to a device in which a resin material is shot into a metal model to obtain a product with a certain shape. In fact, in order to control the temperature of the mold, there are cooling holes, heaters and other devices on the mold that allow the refrigerant to pass through. The material that has become a melt enters the main stream, passes through the diverter, and is shot into the mold cavity at the gate. After the cooling stage, the mold is opened, and the ejector device on the forming machine will push the ejector rod out and push the product out. The forming product is composed of a main channel for the flow of molten resin, a diverting channel for guiding the molten resin into the mold cavity and a product. We usually design the length of the diverter to be equal. The main channels and diverters in the formed products are not products and are sometimes discarded or crushed and reused as forming materials. We call it backloading. The return material is generally not used as a molding material alone, and is usually used after mixing with new materials. This is because after a molding, the mechanical properties, fluidity, color and other characteristics of the resin will change.

Precision injection mold processing features

1) Excellent material

The main materials of high hardness molds are mostly made of high-quality alloy steel, especially those with high life, which are often made of Letenite steel such as Crl2 and CrWMn. This kind of steel has strict requirements from blank forging, processing to heat treatment.

2) Strong ductility

Most of the operating standards for injection molding shell processing are very extreme, and some often bear a large impact load, which leads to brittle breakage. In order to avoid sudden brittle fracture of mold parts during work, high-precision hardware molds should have high hardness and ductility.

3) The shape is complex

Some products such as automobile covering parts, aircraft parts, toys, household appliances, the shape of the surface is composed of a variety of curved surfaces, so the injection mold processing cavity surface is very complex. Some surfaces must be treated mathematically.

4) High imitation accuracy

Sometimes there is no pattern or data in mold production, and the copying process must be carried out according to the actual object. This requires high imitation accuracy and no deformation.

5) Short service life

The use of repeated production molds has a life. When the use of a mold exceeds its life, it is necessary to replace a new mold, so the production of injection mold processing is often repetitive.

6) High precision requirements

A pair of molds is generally composed of a concave die, a punch and a die frame, and some may also be multi-piece integrated modules. Therefore, the combination of upper and lower die, the combination of insert and cavity, and the combination between modules require high machining accuracy. The dimensional accuracy of precision molds is often up to μm level.

Precision plastic mold design and manufacturing process

1) Design and approval of plastic products

Modeling of plastic products according to customer needs or designers, detailed description of plastic products through engineering drawings, and approval by relevant departments.

2) Plastic mold structure design

According to the plastic product drawings, plastic mold structure design, including mold frame design, waterway design, ejection mechanism design, pouring system design.

3) Electrical discharge machining

According to the plastic mold drawings for EDM machining, this process requires the production of electrodes, through computer digital control (CNC) for accurate positioning and machining.

4) Plastic mold grinding

After the electrode machining is completed, it is necessary to polish and grind to ensure the smoothness of the die surface.

5) Mold heat treatment

Heat treatment may be required to improve the hardness and wear resistance of plastic molds.

6) Plastic mold assembly

After the mold parts are manufactured, plastic mold assembly is required.

7) Test the mold

After the assembly of the plastic mold is completed, it is necessary to test the mold to check whether the size, shape, surface quality of the mold and the quality of the molded plastic products meet the requirements.

8) Correction

If necessary, repair the plastic mold according to the test results.

9) Final detection

After the plastic mold modification is completed, the mold test and final inspection are carried out again to ensure that the plastic mold meets all quality requirements.

10) Plastic mold delivery

After the completion of the inspection, packaging, delivery, and final delivery to the customer.

Precision injection mold processing equipment needs requirements

1) The machine tool should have good rigidity and large load capacity commensurate with the weight of the module;

2) The size of the working table should be adapted to the shape of the mold, generally rectangular or square and round, not narrow and long, and the height direction and its stroke require a larger space.

3) To have high accuracy and accuracy retention;

4) To be able to quickly and efficiently remove the surplus, and have high reliability to maintain continuous long-term load operation;

5) In order to adapt to complex spatial surface processing, and there is a large amount of processing, it is required that the machine tool can be multi-axis linkage, and is equipped with a large information capacity of the CNC system.