News

- Industry news

Industry news

Rubber science - perfluorinated rubber

What is perfluorinated rubber?

Perfluorinated rubber refers to the terpolymer of perfluorinated (methyl vinyl) ether, tetrafluoroethylene and perfluoroethylene ether. Also known as perfluoroether rubber. It has the elasticity and thermal and chemical stability of teflon. Long-term operating temperature -39~288 degrees Celsius, short-term up to 315 degrees Celsius, below the embrittlement temperature still has a certain plasticity, hard but not brittle, flexible. Stable for all chemicals except swelling in fluorinated solvents. Perfluoro (hydroxymethacrylate) ether, tetrafluoroethylene and a small amount of perfluoro ethers were prepared by emulsion polymerization with whole heart acid sellae as moistening agent, magnesium perhydroxide and sodium bisulfite as initiator at working pressure of 1.4~4.2MPa and temperature of 40~100 degrees Celsius. Vulcanized rubber by bivalent nuclear substitution of diamine or 2,2 '-bis (4-phenyl-butane) with fluorine in the perfluorophenyl ring.

Characteristics of perfluorinated rubber

1. Excellent chemical stability

Perfluorinated rubber has excellent resistance in strong acids, strong alkalis, organic solvents and oils, and is not susceptible to chemical erosion, which can ensure long-term stability and reliability.

2. Excellent high temperature performance

The thermal stability of perfluorinated rubber is very high, can be used in the range of -20 ° C to +300 ° C, and can still maintain its physical properties and chemical stability at high temperatures.

3. Excellent low temperature performance

Perfluorinated rubber still has good elasticity and wear resistance in low temperature environments, and does not produce hardening and cracking phenomenon, ensuring that it can work normally in extremely cold environments.

Perfluorinated rubber common processing technology

1. injection molding

Perfluorinated rubber using this process can be used in low and medium Mooney viscosity (20-60MV), good scorch safety and fast vulcanization grades.

2. injection molding

Perfluorinated rubber using this process can adopt low Mooney viscosity and medium Mooney viscosity (20-60MV), and have good scorch safety grades, so as to avoid scorch during injection pressure.

3. plate molding

Perfluorinated rubber using this process can use high Mooney viscosity (50-90MV), vulcanization speed of the grade.

4. extrusion molding

Perfluorinated rubber using this process can be used with low Mooney viscosity (20-40MV) and good scorch safety grades. In many cases, processing AIDS can be used to improve fluidity and surface finish.

5. coating molding

The viscosity of the solution is determined by the amount of solvent and filler selected. The stability of the solution (storage period) is the primary issue to be considered.

Fluoro rubber and perfluoro rubber difference

1. the difference between fluorine rubber and perfluorinated rubber

Fluorine rubber in the external environment has a good oil resistance, solvent resistance, corrosion resistance, but also a certain high temperature, low temperature resistance. Its hardness is relatively high, generally between 70 and 85. In contrast, perfluorinated rubber has better chemical resistance, more fluorocarbon bonds in its structure, and more dense molecular chains. Perfluorinated rubber is not only better than fluorine rubber corrosion resistance of acid, alkali, salt and other substances, but also can withstand higher temperature and pressure. In addition, perfluorinated rubber also has good low temperature elasticity and UV resistance.

2. fluorine rubber and perfluorinated rubber use difference

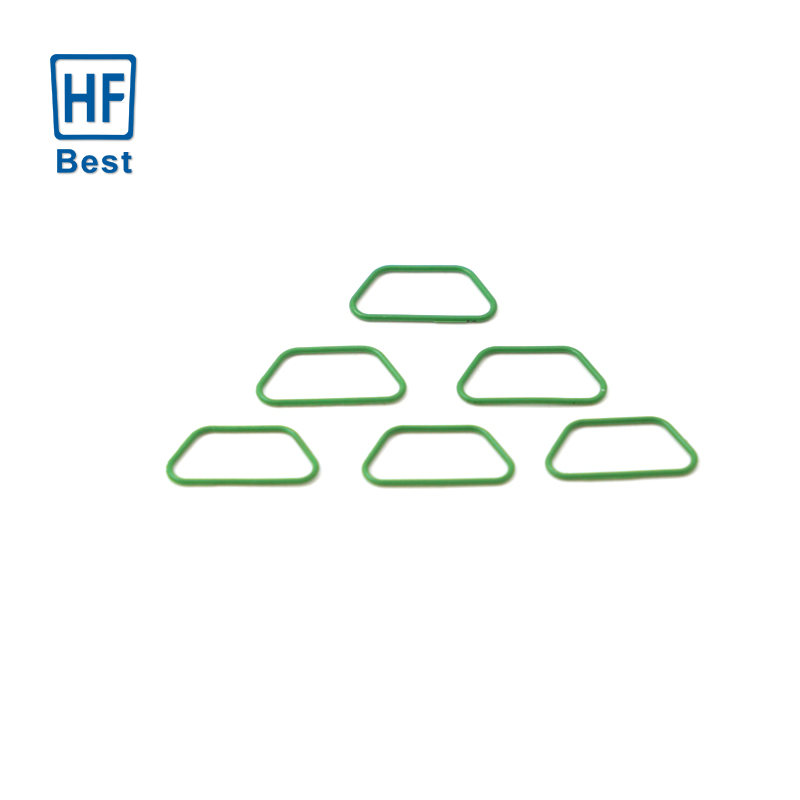

Due to its chemical stability and excellent corrosion resistance, fluororubbers are commonly used in the manufacture of products such as seals and pipes. Fluorine rubber can also resist the corrosion of most organic and inorganic chemicals, so it is also widely used in chemical, pharmaceutical, food and other fields. Perfluorinated rubber is more widely used, both to replace fluorine rubber, but also to replace other types of rubber such as silicone rubber. The high temperature, low temperature and ultraviolet resistance of perfluorinated rubber also make it widely used in high-tech fields such as aviation, aerospace and semiconductors.